Contact Us: +91 - 94429 00071 | 81225 77729 || Mail : amritaengineeringcompany@gmail.com

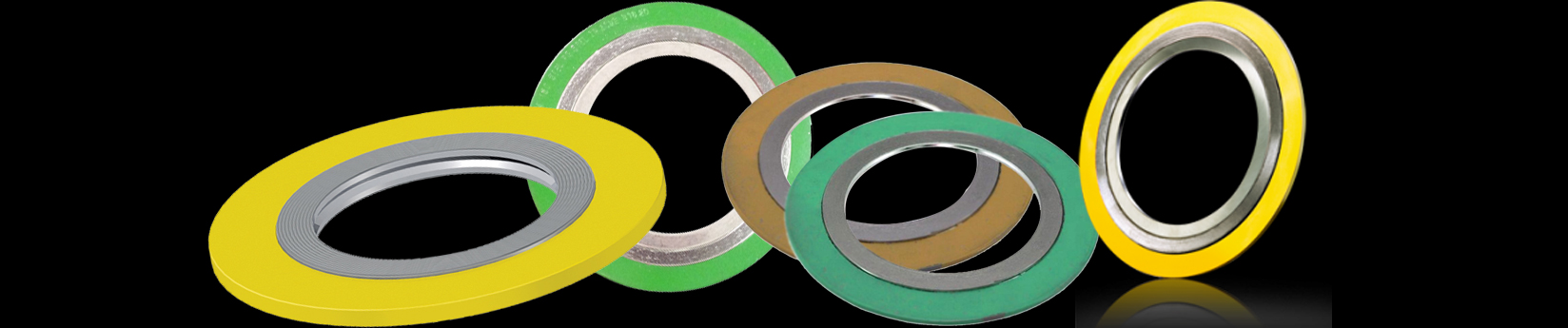

AMRITA ENGINEERING COMPANY established in-house facilities for manufacturing different types of gaskets and also offering wide range of custom made gaskets as per drawing to suit piping/equipment flange joints.

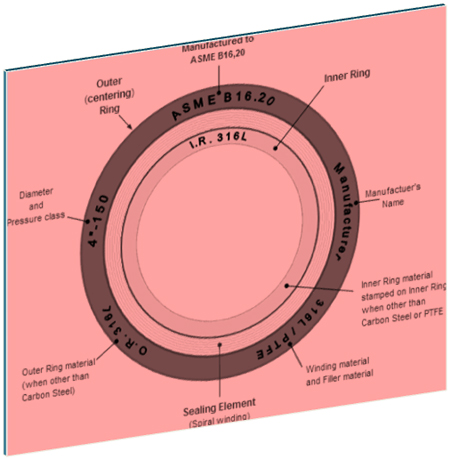

Our regular spiral wound gaskets are manufactured as per relevant codes of ASME , ANSI, EN, DIN, BS

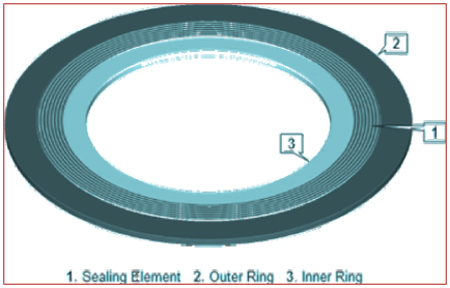

Spiral wound gaskets are produced by spirally winding a “V” formed metal strip (SS 304/SS304L, SS316/SS316L,SS321 etc) and a strip of non-metallic filler material (Graphite,PTFE/TEFLON,Ceramic).

Outer rings/centering rings are normally of carbon steel.Inner rings are usually made of the same material as the gasket metallic strip. A few plant owners normally use of SWGs without inner rings but it is preferred that SWGs with inner rings for its long life.

|

|

| PLEASE SPECIFY | EXAMPLE |

| GASKET STYLE | SWG with OR and with IR |

| SIZE | 2” |

| PRESSURE RATING | 150 class |

| GASKET STANDARD | ASME B16.2 |

| WINDING MATERIAL /WINDING STRIP | 304 |

| FILLER MATERIAL | Graphite |

| OUTER RING MATERIAL | CS |

| INNER RING MATERIAL | 304 (If inner ring required ) |

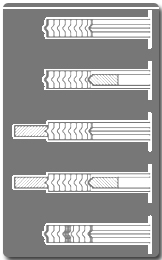

| GASKET STYLES | SWG with OR and IR |

| SWG with OR and without IR | |

| SWG with IR only and without OR | |

| SWG without OR and without IR | |

| SWG with PTFE/TEFLON sealing zone, no OR, no IR |

| SIZES | PRESSURE RATING IN LBS | GASKET STANDARD |

| ½ INCH TO 24 INCH | 150, 300, 400, 600, 900, 1500, 2500 | ASME B 16.2 FOR ASME B16.5 FLANGES |

| 26 INCH TO 60 INCH | 150, 300, 400, 600, 900, | ASME B 16.2 FOR ASME B16.47 SERIES-A FLANGES |

| 26 INCH TO 60 INCH | 150, 300, 400, 600, 900, | ASME B 16.2 FOR ASME B16.47 SERIES-B FLANGES |

| DN 10 TO 3000 | PN 10 TO PN 400 | EN 1514-2 gaskets for EN 1092-1 FLANGES |

| WINDING STRIP | FILLER MATERIAL | OUTER RING MATERIAL |

| STANDARD PRACTICE | STANDARD PRACTICE | STANDARD PRACTICE |

| SS 304 | GRAPHITE | CARBON STEEL |

| 304L | PTFE/TEFLON | |

| 316 | CAF/ASBESTOS | |

| SPECIAL APPLICATIONS | SPECIAL APPLICATIONS | SPECIAL APPLICATIONS |

| 321 | PTFE | 304 |

| ALLOY 20 | CERAMIC | 304L |

| MONEL | 316 | |

| DUPLEX | ALLOY 20 | |

| SUPER DUPLEX | ||

| HASTELLOY C276 |

Copyright 2016 | All Rights Reserved